New 14 MW electric boiler increases the flexibility of energy production and reduces overall emissions from production.

The electrification of energy production helps to achieve climate goals and optimise production. For Nevel, transitioning from fossil fuels to clean electricity is not only a responsible act, but it also supports the flexible use of different energy sources and enables participation in the electricity reserve market.

Electric boilers can produce carbon-neutral heat and steam in a cost-effective manner and can be part of a hybrid system in combination with boilers powered by traditional fuels. This way, heat production can be optimised because electricity is used when the production cost is lower than the alternative combustion-based production form.

Nevel has continued to invest in electrification solutions at selected plants around Finland. In addition to Forssa, investments are planned at the company’s Karkkila, Ii and Jokela heating plants. Nevel has also announced numerous projects in cooperation with its industrial customers.

Nevel has made a number of investments at the Forssa plant aimed at phasing out fossil fuels, digitalising production and expanding energy sources. The plant currently also uses solid recovered fuel (SRF), which enables a local circular economy and minimises waste from industrial and commercial sources.

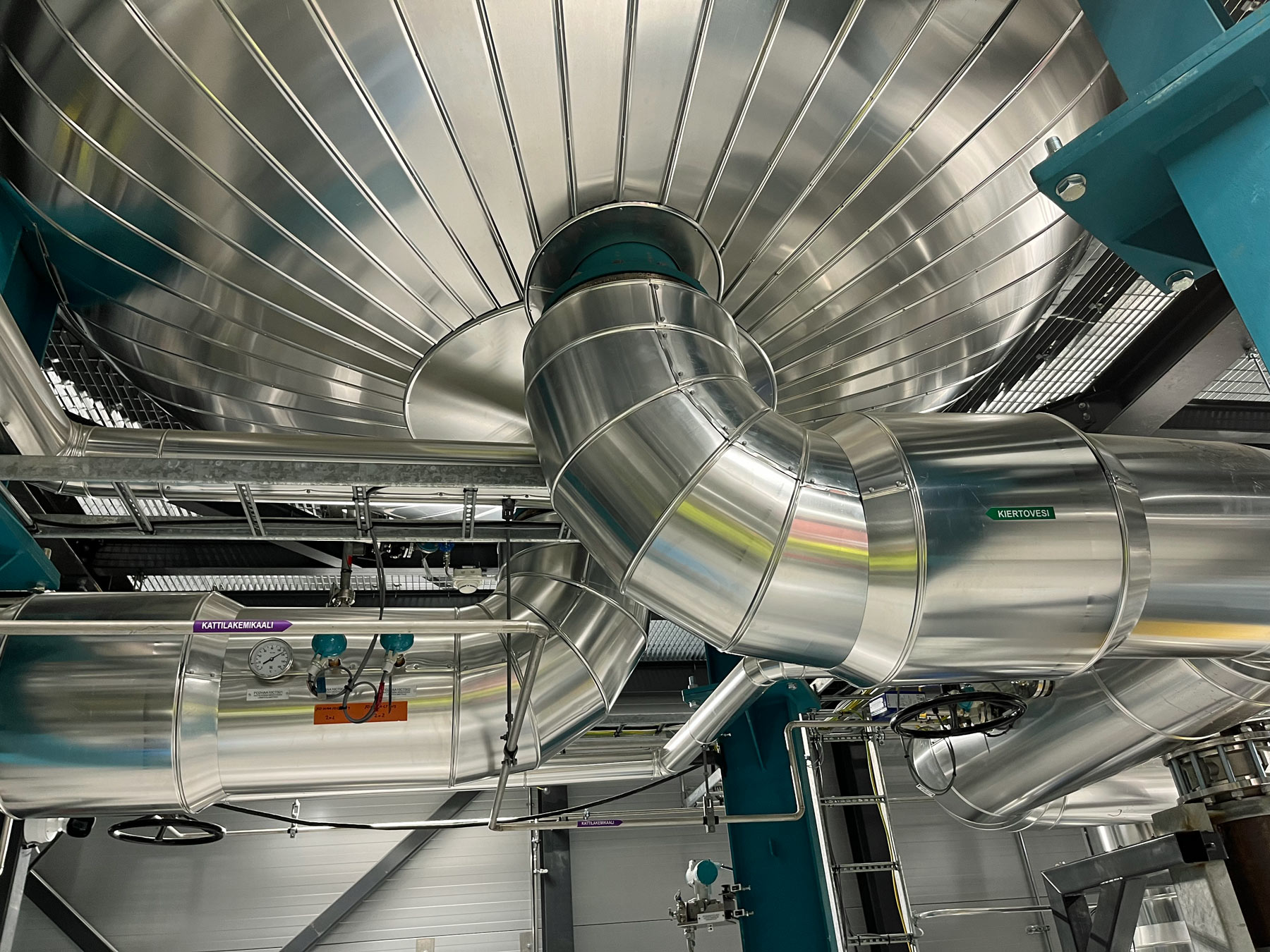

The electric boiler began operating in early 2025 according to the planned schedule and has been in remote operations 24/7 since the spring.

With the introduction of the electric boiler at Forssa, Nevel will be able to optimise heat production with the help of automation. The electric boiler will be used in place of the plant’s solid fuel boiler during the summer months and minimises the need to use the plant’s standby oil boiler, enabling CO2 emission reductions of around 1,200 tons. The change also adds flexibility and strengthens security of supply, for example during maintenance breaks. In addition to the electric boiler, Nevel is also investing in a new district heating pumping unit, which will reduce oil combustion in the winter as the power plant’s district heating output improves.

“Energy production is becoming electrified, and the new electric boiler at Forssa is a good example of this. By utilising artificial intelligence and machine learning, we can optimise heat production in a fast cycle. The emission-free heat produced by the electric boiler can also be stored in a battery for later use if there is no demand in the network at the time the heat is produced,” says Ilkka Koskinen, Director of Real Estate solutions production at Nevel.

More information

Hanna Viita, Director, Sustainability and Communications, +358-40-1671755

Nevel in brief

Nevel is a utility infrastructure company offering advanced industrial and real estate infrastructure solutions that are fit-for-purpose and future-proof. Committed to climate-positive growth, Nevel drives societal impact by co-creating local circular economies and driving transformation to CO2 carbon-neutral energy production. Nevel serves almost 100 industrial and over 5,000 real estate customers with decentralised energy and circular economy solutions. The company operates more than 130 energy production sites and manages over 40 district heating networks. Nevel has an annual turnover of EUR 150 million, and employs 190 experts in Finland, Sweden and Estonia.

The electrification solution further reduces fossil fuel use at Forssa power plant.