District heating has long been known for its high availability and reliability. For our industrial, real estate and private customers, this means a comfortable indoor climate and access to energy all year round. To optimise energy production even better, Nevel is now introducing smart maintenance based on artificial intelligence at the heating plant in Hultsfred, Sweden. Omid Montinola, Head of Operations and Maintenance in Real estate solutions business in Sweden, explains the way forward.

– Our employees are constantly looking for operational improvements to secure the distribution of energy in the district heating networks. We are now measuring critical data such as vibrations on rotating equipment, including fans and pumps, in Hultsfred. We will evaluate the results using artificial intelligence (AI). It is about condition-based preventive maintenance.

Smart maintenance prevents plant unavailability

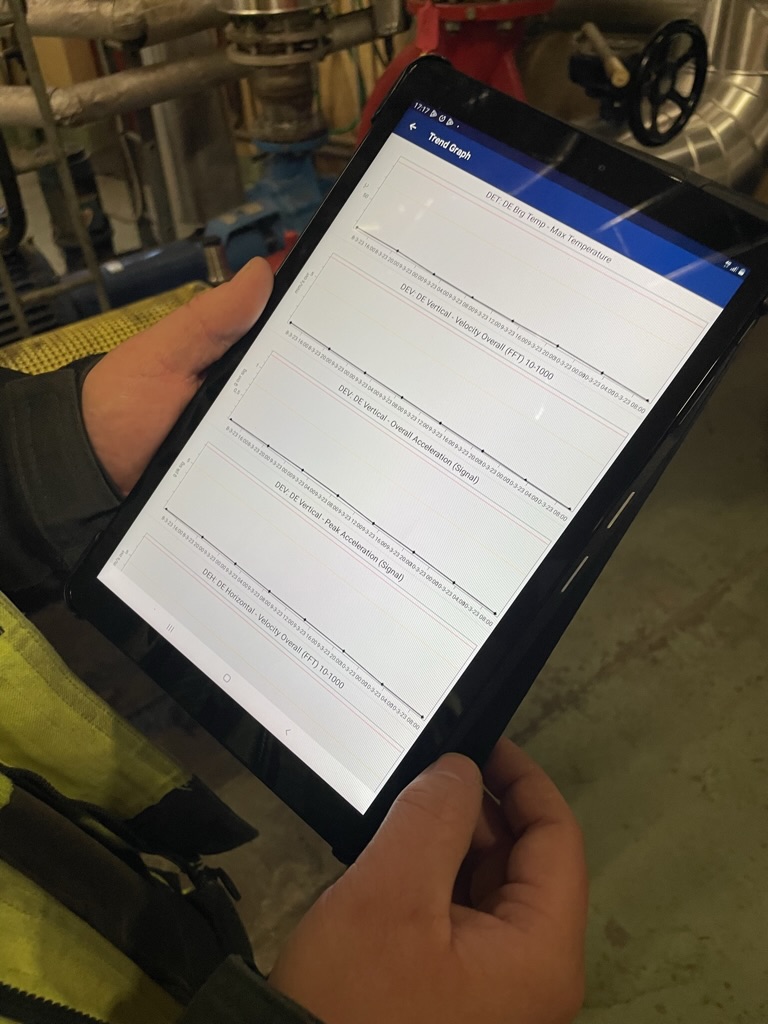

Also known as smart maintenance, this method helps detect problems beforehand, such as prevent poor lubrication or bearing wear. At larger energy production sites, online measurement is usually installed, but at smaller sites the equipment can be moved around and mounted on a fan, and run for half a day to collect data. The mobile equipment consists of several sensors and a tablet that displays results real-time. The data is transferred to a computer for evaluation using the AI software. By collecting data of the site, input is provided for a maintenance plan.

– We tested and evaluated the system during the spring and now we have decided to take it into use more broadly, says Omid.

The benefit of smart maintenance is above all to prevent issues beforehand. In the worst case, unforeseen problems can lead to unavailability issues of a certain part of the site, which is costly especially during the winter.

– With the new system, we can learn more about the condition of the equipment at the site and how it performs. In new projects we can have it as a standard requirement and compare the actual data with the original plan. That means, after taking over a project we don’t end up with problems with our equipment. The goal is availability and reliability for our customers, but also a better working environment for our employees by avoiding unplanned interruptions that can occur at any time of the day or night, concludes Omid Montinola.

More information

Hanna Viita, Director, Sustainability and communications, Nevel

+358 40 167 1755

Hanna.viita@nevel.com

Nevel in brief

Nevel is a utility infrastructure company offering advanced industrial and real estate infrastructure solutions that are fit-for-purpose and future-proof. Committed to climate positive growth, we drive societal impact by co-creating local circular economies and driving transformation to carbon-neutral energy production. Nevel serves almost 100 industrial and over 5,000 real estate customers with decentralised energy and circular economy solutions. The company operates more than 130 energy production sites and manages over 40 district heating networks. Nevel has an annual turnover of EUR 115 million, and employs 190 experts in Finland, Sweden and Estonia.

Data is collected via a sensor mounted on the equipment.

The mobile equipment consists of several sensors and a tablet that displays results real-time.