Sustainability

At the beginning of a new era towards decarbonisation

Energy industry has taken leaps to develop solutions towards carbon neutral energy. Now we are facing a new era and are at the beginning of a longer journey. The role of power and heating is changing. We are in a transition from fossil fuels to bioenergy, from biofuels to non-combustion and use of electricity. This transformation requires future foresight, planning, cooperation among players, and concrete actions. The transition towards decarbonisation must be just, taking into consideration social, economic and environmental impacts. All these factors are crucial towards the joint vision and minimising negative side effects. Together we are part of a movement providing solutions to climate and biodiversity. Every action contributes to a bigger goal.

Our promise is next‑level utility infrastructure

At Nevel, sustainability is the key driver for our entire business. We believe it enhances safety and wellbeing, as well as builds competitive edge for us and our stakeholders. We are committed to building a green transition and a climate-positive future where people, communities and businesses can prosper. We drive this change with our sustainability approach, which is based on three pillars:

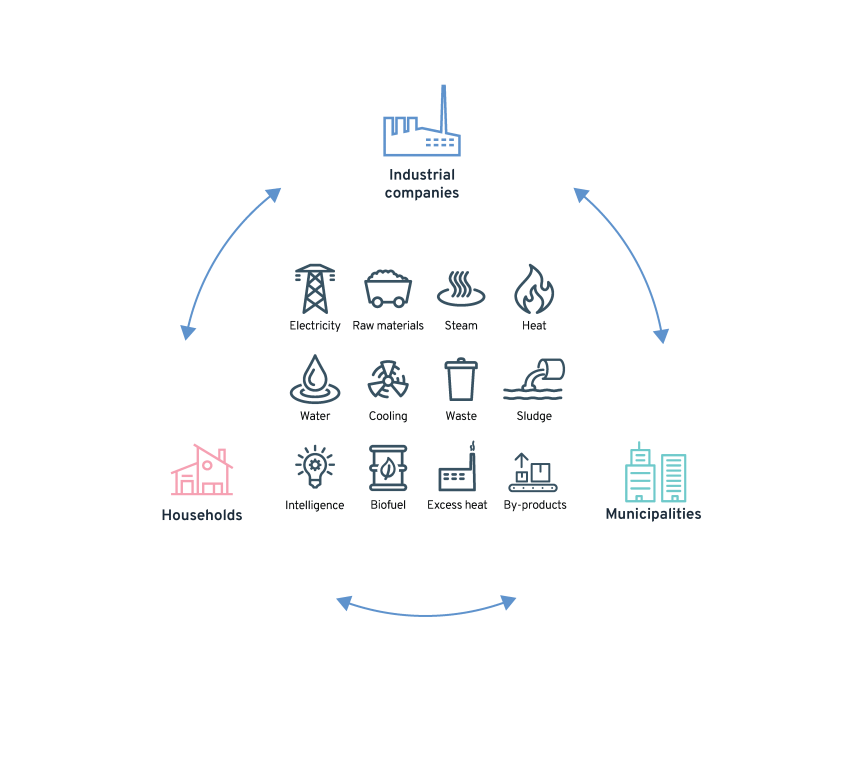

Co-creating local circular economies

Driving transformation to CO2 emission free energy production by 2030

Building a high safety culture and sustainable and transparent corporate citizenship

Co-creating local circular economies by developing energy and material flows and the use of side-streams. Realising synergies and benefitting society as a whole, including our customers such as municipalities, industries and district heating customers.

We are committed to driving and promoting the use of side-streams and building transformation with our customers. This includes working together with local communities and industries, and increasing understanding of the use of side-streams and circular economy. We build and innovate new concepts enabling technology neutral transition to carbon neutral operations and increase the share of side-streams used in energy production.

During 2021 we increased the use of side-streams and improved energy efficiency at our own power plants by installing five flue gas condensers in Finland and one in Sweden. Together with our industrial and municipal customers, we have developed concepts to build local circular economies and paths towards CO2-emission free energy production, enabling a just transition to decarbonisation even in smaller towns.

Creating sustainable bioeconomy in cooperation with the City of Lieksa in Finland

The cooperation has focused on district heating and industrial heating solutions, as well as creating economies of scale from increased municipal and industrial cooperation. Nevel has been running Lieksa’s district heating network for over twenty years, and nowadays, sawdust and bark from the local sawmill make up over half of the fuel needed to create heat for the entire municipal network, as well as for the mill itself. This reduces fuel-related waste and transport emissions, and enables a resource-efficient municipal ecosystem. Find out more about our cooperation (in Finnish).

Co-operation with Lieksa municipalitySubstantial emission reductions with heat recovery and bioheat replacing oil use

Supporting Sandvik Coromant reduces emissions and transition towards carbon neutral production. The partnership reduces greenhouse gas emissions by up to 1,850 tonnes per year, equalling the annual emissions of 1,200 cars. The carbon dioxide emissions are reduced and now close to zero.

Supporting Sandvik Coromant

Driving transformation to CO2 emission free energy production by 2030 by investing in renewable energy, modernising heating plants and district heating networks, optimising energy use, minimising use of fuel and flue gas residual oxygen level and increasing the use of side streams and excess heat.

We are committed to reducing CO2 emissions in our own energy production and to building transformation roadmaps together with our customers, as well as increasing the share of side-streams and circular economy solutions.

During 2021 we reduced our CO2 Scope 1 emissions for sold energy by 35% and grew our share of renewable energy production by 12% to 75%.

Digitalisation helps optimise energy and material flows

With better access to information, energy and material flows can be optimised for reduced emissions and reduction of residual products and waste. With Nevel Remote operations and maintenance platform implementation at our own plant in Forssa, we have been able to optimise the combustion process and reduce residual oxygen levels, CO2 and NOx emissions.

Towards CO2 emission free energy production

In 2021 Nevel decreased its CO2 Scope 1 emissions for sold energy by 35%

Read more

Building a high safety culture and sustainable and transparent corporate citizenship

We believe that every act counts. We are committed to building a culture that provides a good and safe working environment for us, our customers and our partners. Our safety agenda is based on zero injury principle and focuses on preventive safety measures. We monitor the commitment through our internal and partner programs.

In January 2021 Nevel was transferred to ownership of Ardian Infrastructure, a world-leading private investment house. Corporate governance structures were put in place to support and promote high-quality decision making and leadership, and environmental and social governance was placed firmly at the top of the agenda, with an increased focus on safety. A sustainability programme was launched to provide a focus across the organisation on a green transition and a climate-positive future.

Since Nevel was established,

sustainability has been on top of our agenda

Based on internal assessments on sustainability and safety, we have identified key focus areas and gaps, and worked on a long term roadmap that gives us direction. We believe it is our responsibility to build high class safety culture, reduce emissions and waste, and demonstrate benefits of local circular economies. Together with our customers and partners, we are part of a wider energy and material ecosystem providing solutions to the world’s climate and biodiversity. This requires a common way of working, and we expect the same from everybody involved in our value chain.

Code of conduct

Sustainable Development Goals

The 2030 Agenda for Sustainable Development, adopted by all United Nations Member States in 2015, provides a shared vision for global sustainability. The 17 Sustainable Development Goals (SDGs) of the Agenda are a call for action, action taken in global partnership and by all – states, organisations, individuals, and companies.

Nevel is committed to enhancing the implementation of the Sustainable Development Goals. With our core business, we focus especially on the following Goals.

7 – Affordable and clean energy

We strive to become CO2 emission free in our own production by 2030. We support our customers’ technology neutral transition towards CO2 neutrality.

8 – Decent work and economic growth

We are committed to offering our employees, partners and visitors a safe, healthy working environment by using methods that prevent injuries and accidents and promote well-being at work. We utilize our working instructions and the competence of our personnel to identify and mitigate risks and hazards.

9 – Industry, innovation and infrastructure

We build advanced utility infrastructure for and together with industries and municipalities and innovate new concepts.

We strive to be part of a wider energy and material ecosystem.

We ensure security of supply for energy.

12 – Responsible consumption

and production

Together with our customers and partners, we co-create local circular economies, e.g. by utilising side streams and excess heat and minimising waste. We enable technology neutral transition to carbon neutral operations and increase share of side streams and certified wood used in energy production. We promote and increase understanding of circular economy.

15 – Life on land

We support biodiversity by working together with biofuel suppliers, ensuring sustainable practices.

We use certified, residual wood fit for purpose.

Nevel achieved record reduction in CO2 emissions and increase in renewable energy production to 75%

According to Nevel’s 2021 sustainability report, the company decreased Scope 1 carbon dioxide emissions of sold energy by a record 35% in 2021. The decrease in emissions and increase in energy efficiency was predominantly achieved by piloting new technologies, optimising fuel use and investing in renewable energy. For example, Nevel conducted site conversions to phase out using peat as fuel in the Finnish cities of Forssa and Lieksa. The share of renewable energy in Nevel’s own energy production reached the company’s target of 75%.

Download the report Read press release