How the carbon neutrality target is transforming industrial gas use – Local solutions

September 3, 2020- InfraTalks – utility infrastructure insight

Almost all natural gas in the Nordics is used by industry or for energy production. This is very different from the situation in central Europe, where households are also significant consumers of natural gas. While natural gas is a fossil fuel, it emits only 50% of the carbon dioxide released by coal to produce the same amount of energy. This is a significant difference, as an increasing number of industrial operators are committed to achieving carbon neutrality in a short period of time. At Nevel, together with our clients we often plan what type of future role gas plays in their carbon-neutral energy production roadmap.

Harnessing all available options

Reaching carbon neutrality is a demanding goal that requires making use of any and all good measures available. There is no single magic-bullet solution to achieving carbon neutrality; every responsible player in the industry must take a long, hard look at themselves and come up with a solution that works best for them. However, natural gas has several favourable qualities that can make it an integral part of the solution going forward. These include simple scalablility to meet energy demands, competitive pricing due to the opening up of gas markets, and easy storability. In part one of this blog we take a look at local solutions as alternatives, while in part two (to be published later) we’ll take a more in-depth look at the potential of renewable gas.

Low-temperature applications going electric

The first step at the concept stage is to identify potential ways to reduce natural gas usage. For applications operating in conditions well below 150°C, good local alternatives to gas include priming waste heat from production to other stages of the process using high-efficiency heat pumps. This method is applicable to any low-temperature application, including waste heat in wastewater, cooling-related heat loss through roofs, or even geothermal heat from deep underground. In this case the most significant sources of waste heat in production have to be identified and prioritised.

Utilising side streams

Once the major sources of waste heat have been identified, the next step towards carbon neutrality is identifying material side streams. In the food industry, for example, the opportunities lie in gasification (anaerobic digestion) of any organic waste or side products. At many sites local agricultural activities, through manure and biomass from the fields, provide significant additional potential for local biomethane production, in addition to utilising on-site material side streams. According to Finnish Biocycle and biogas association, in terms of raw material potential, biogas could fulfil one sixth of the current demand for natural gas by 2030. Investments can be kept to a minimum by directing reactor-produced biogas directly to the existing application such as a steam boiler burner.

A long-term perspective

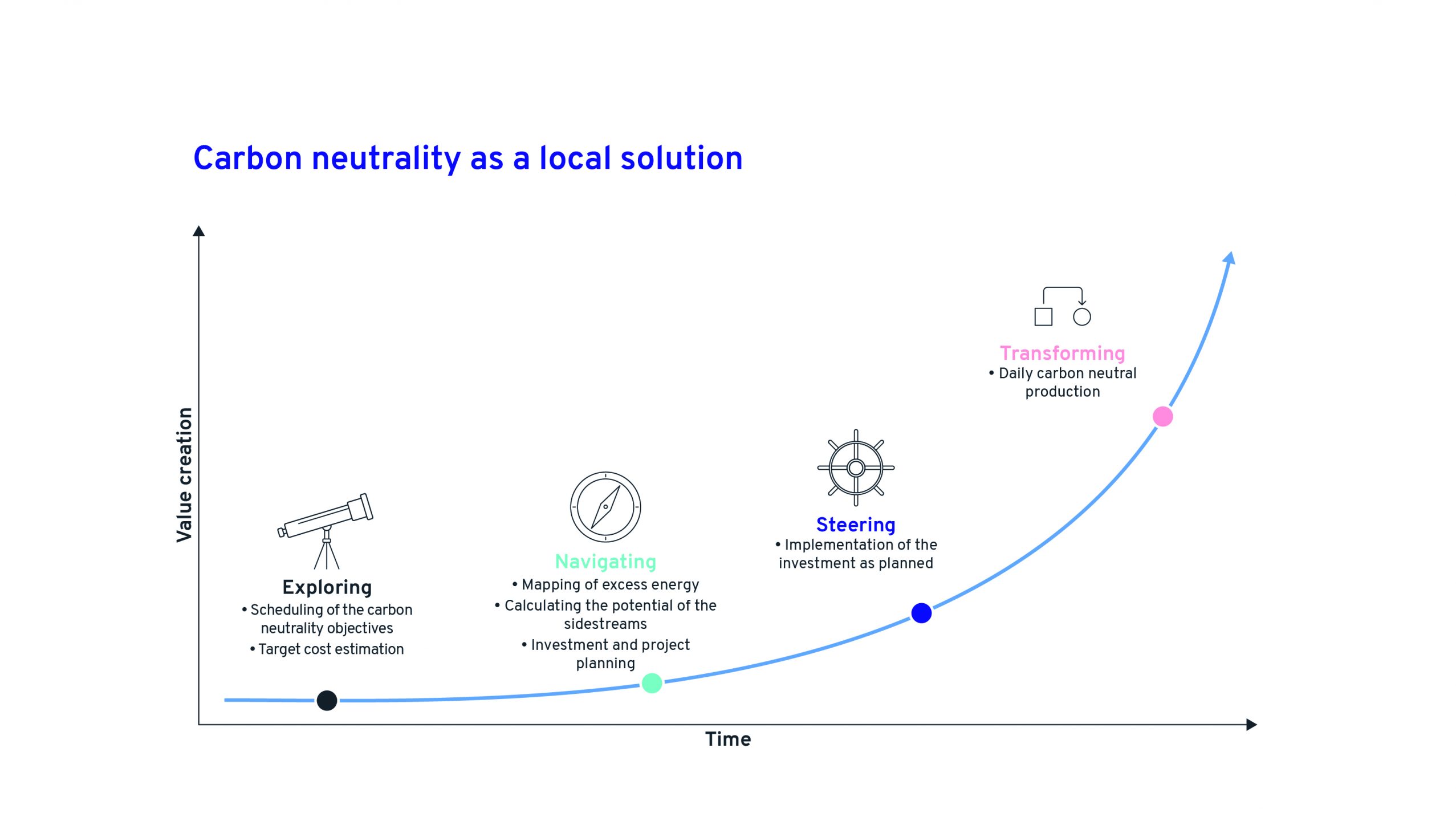

Whether the most attractive solution is priming waste heat, utilising material side streams, or something else entirely, detailed engineering and investment decisions inevitably lie ahead. It’s a therefore a good idea to take a long-term perspective, together with an expert partner, and consider how to share the investment burden. The emphasis here should be on ensuring that the benefits best serve business efficiencies, that the focus is on the development of core operations, and that the change project can be implemented cost-efficiently and risks managed professionally within a short timescale. Many of our industrial clients are currently implementing, or have already implemented, their own roadmaps towards carbon neutrality. As your expert partner, we are here to help you find the best solutions for both project planning and investment purposes at both the concept and implementation stages.

Co-creation map towards a carbon neutral future

In my next blog post, we look at alternatives made possible by buying renewable gas from the markets when local alternatives have been exhausted.

We are happy to help you with your goals related to carbon neutrality, resource efficiency or other energy or material related infrastructure development projects. Please contact Teemu Klingberg for further discussions.

Teemu Klingberg

Director, New ventures

+358 50 317 1448